(1).jpg)

The Corona year 2021, Labelprint24.com and the consequences of the pandemic for the printing industry

- After two years of pandemic, Corona continues to determine everyday life in society and the economy - the printing industry is also struggling with the consequences of the crisis

- Despite many limitations, Labelprint24.com is looking positively into the future - the double-digit growth in 2021 is to be continued

- Especially in the field of advertising printing, many companies in the printing and media industry survived the pandemic only with major losses and state aid

- Heidelberger Druckmaschinen AG is optimistic about 2022 thanks to a savings drive and new business models

- Shortage of raw materials and increased energy and logistics prices continue to cause uncertainty in the industry

- Digitalisation and sustainability are the topics of the future - also for the print and media industry

1. The current situation

Two years after the start of the Corona pandemic, there is still no relief in sight. Even though the WHO is cautiously talking about a possible improvement of the situation in 2022, the further course of the pandemic is more than uncertain. New mutations of the virus, such as the current Omicron variant, and a low vaccination rate have caused the infection figures in Germany to rise extremely in the last quarter of 2021 and at the beginning of the new year 2022 - with renewed drastic effects on society and the economy. Since the first corona cases appeared in China at the end of 2019 and the WHO classified it as a global pandemic on 11 March 2020, there have been 437 million registered infections and over 5.96 million fatalities so far. Despite great medical progress and the development of various vaccines, an end to the pandemic, or the transformation into an endemic considered possible by virologists, is not yet in sight.- In Germany alone there were 14.9 million infections and 123,000 deaths (RKI 01.03.2022)

- by now 62.7 million people in Germany are fully vaccinated, which corresponds to a vaccination rate of 75.3 per cent

The WHO is cautiously optimistic - with a global vaccination rate of 70 per cent by mid-2022, severe courses could slowly run out. Furthermore, the WHO expects further progress in the development of drugs against covid 19. The new omicron variant spreads faster than the delta mutation, but leads to fewer cases with severe courses despite a higher infection rate, according to the WHO.

In industry and trade, the concern regarding Omicron relates primarily to the international exchange of goods if the situation should worsen. The logistics companies generally do not expect any supply-relevant failures and the energy industry also does not see any supply risk from the omicron variant - in the meantime, there is a routine handling of pandemic events.

2. Corona and the printing industry

Printing plants and packaging manufacturers in Germany cannot speak of a Corona routine at the moment, because the pandemic has had some drastic effects on production and led to numerous insolvencies. The poor availability of raw materials and the increased prices for energy and logistics are causing problems.2.1 Labelprint24.com - digital printing and the pandemic

For the online printing company Labelprint24.com, the first weeks of the pandemic in March 2020 were also marked by a great deal of uncertainty. Various concepts were explored to find out how the company would have to position itself in this crisis so that production could continue.

Thanks to a sophisticated hygiene concept and contactless controlled shift operation, orders could still be processed and produced. And the great demand for packaging due to the pandemic-related upswing in e-commerce was soon felt at the production facility in Zeithain, Saxony. The slowly emerging shortage of raw materials did not go unnoticed by managing director Stefan Harder either, and he took precautions as best he could.

Despite all this, there have also been bottlenecks in the availability of certain materials at Labelprint24.com since mid-2021. For example, it was sometimes impossible to get a delivery of natural cardboard because the delivery dates were repeatedly postponed. Thus, the procurement and securing of raw materials is currently also one of the biggest challenges for Labelprint24.com.

Due to the situation on the raw materials market, for example, the company had no choice but to pass on the price increases to customers in November 2021. Nevertheless, Managing Director Stefan Harder can draw a positive conclusion for his company:

"The year 2021 went very well for us - our growth is in a good double-digit range and the outlook for 2022 is also promising: we want to grow further - not only in terms of the number of orders. We will expand our production area by about 10,000 m² by the end of 2022, expand our product range and hire more employees. And through the merger with All4Labels, we have a strong partner at our side since the end of 2021, with whom we can also fulfil our goals in terms of growth and investments."

2.2 Short-time work, insolvency, opportunity - The printing industry after two years of Corona

In other areas of the printing industry, the Corona pandemic has left its mark more clearly in the last two years - due to the strong networking with other industries and the resulting dependence on the most diverse sectors of the economy, there have been three major developments:

- Due to a lack of orders, there was a massive drop in turnover in marketing, events, advertising and tourism

- Increased demand in online retailing led to increased demand for secondary packaging, folding cartons and corrugated cardboards

- The lack of adaptation to the new market situation and economic uncertainties were exacerbated by Corona and could lead to insolvency

A survey conducted by the Bundesverband Druck und Medien e.V. (bvdm) in April 2021 confirmed this development. Only 14 per cent of the companies reported constant or increased sales in 2020, half of the 400 companies surveyed, on the other hand, had to report sales declines of more than 20 per cent - advertising printing was particularly hard hit by a drop in sales. In label and packaging printing, on the other hand, the situation was less serious, with 25 per cent of the companies even reporting increases in turnover.

Due to the lack of orders, volatile production utilisation and because of rising supplier prices, 50 per cent of the companies expected profits to fall in 2021 - a prophetic 80 per cent also expected prices for printing papers to rise.

Many companies were only able to survive in 2020 because of the short-time allowance, which was taken up by 80 percent of the companies. Nevertheless, the development was not without consequences - in addition to the cancellation or postponement of investments, almost two-thirds of the companies expected job cuts in 2021.

Dhe number of insolvencies in 2020 remained surprisingly below the previous year's level of 91 with 84 - 118 company closures had been forecast. For 2021, Apenberg & Partner expects 104 insolvencies, which, however, could not yet be verified.

The year 2021 was perceived more positively again by the industry - in the autumn forecast by Apenberg & Partner, 83 per cent of the 118 companies surveyed expect increasing results and two-thirds of the companies in the publishing industry even anticipate higher personnel requirements.

Nevertheless, the pandemic and the accompanying economic difficulties are not yet over. Even if the printing industry as a whole has not been hit as hard as feared, the current price trends for raw materials, energy and logistics are worrying. After all, 97 per cent of respondents expect supplier prices to rise and 72 per cent anticipate an increase in customer prices in 2022.

Flexibility is needed for the future - because the focus on the new needs of customers can also offer new opportunities for businesses in the long term.

2.3 Ways out of the crisis - Heidelberger Druckmaschinen AG

Despite its role as world market leader in the manufacture of sheetfed offset presses, Heidelberger Druckmaschinen AG was forced to put some of its workforce on short-time working even before the Corona pandemic. The negative climax of this development came in 2020, when at times less than ten per cent of the workforce was present and the main plant in Wiesloch was in a kind of emergency mode.

Due to the recovery of the markets in 2021, new business models, an improved operating result and increasing demand in the core business, Heidelberger Druckmaschinen AG was able to end short-time work for the 4300 employees at the end of December 2021.

This was made possible by a strict cost-cutting policy - the launch of the restructuring programme in March 2020, however, also meant the elimination of 2000 jobs. The reorientation took place through a focus on the profitable core business with sheetfed offset presses and the separation of floor space and peripheral activities. In combination with digital business models and offerings outside the traditional business, such as wallboxes for charging e-cars, the company is optimistic about the future.

A "gamechanger" for the company could be the partnership with Munich-Re as an investor in the subscription business - a kind of subscription model in which the customer does not buy the press but only pays for the print volume.

In response to the current developments, the company's own vaccination centre was also reactivated in December, where approximately 2,000 employees had already received their corona vaccination in June/July 2021. Overall, 85 per cent of the workforce has been vaccinated or recovered. The implementation of the 3G rules is therefore not a problem for the company, even though the pandemic and the tests, protective masks and disinfectants provided have resulted in additional costs in the mid-six-figure range.

Despite the worldwide shortage of raw materials, logistics problems and a corona-related volatile parts supply, the company is optimistic about the future. Thanks to long-standing relationships with suppliers and a high level of vertical integration, the shortage of materials and problems in the supply chains can still be compensated for at present. Only the delivery of the finished presses may be delayed due to a lack of containers.

3. Corona as a catalyst

The shortage of containers is indicative of an ever-increasing problem associated with the Corona pandemic - rising freight costs, shortages of raw materials and high energy prices. On the Shanghai-Rotterdam route, a 40-ft container cost USD 2,000 in January 2020, USD 8,800 in January 2021 and USD 13,475 in November 2021 - caused by the blockade of the Suez Canal and conditioned by Corona outbreaks in numerous ports around the world. A development that has also become a major challenge for the printing industry.3.1 Raw materials, energy and logistics - the expensive consequences of the pandemic

This is because the import of pulp for paper production from South America and Asia is only possible to a limited extent due to the problems in logistics, which led to a price increase of 45.7 per cent in September 2021 compared to the same month of the previous year. However, the cost explosion in raw materials, energy and logistics as a result of the Corona pandemic is not the only reason for the printing industry's problems - the acute paper shortage is having at least as detrimental an effect on companies' business.

This is also confirmed by the results of the High Volume Printers Forum of 23 November 2021 - the reduction of production capacities and the shift in the production of graphic paper to the manufacture of packaging material has resulted in higher purchase prices. This creates an acute shortage of waste paper, which in turn is an important raw material for cardboard and paper production.

In the last ten years, the production of graphic paper has declined by 32 per cent - paper mills have been closed or converted to the production of packaging materials. Whereas 6.62 million tonnes were still produced in 2010, the figure was 5.07 in 2019 and as low as 4.49 million tonnes in 2020. In the case of newsprint, production has fallen by 42.6 per cent, in the European Union by 22.2 per cent.

This recovered paper is now missing, as the raw material accounts for 80 per cent of paper production. As a result, the wholesale price for a tonne of mixed waste paper rose to 170 euros in August, an increase of 222.4 percent compared to the previous year. The import price for importing recovered paper rose by 75 per cent. It also does not help that 99.3 per cent of paper waste in Germany is recycled - because the 6.98 million tonnes of recovered paper that were recycled in 2019 are 13.7 per cent less than ten years ago.

In contrast, corrugated production rose from 1.61 million tonnes in 2010 to 4.36 million tonnes in 2020 - an increase of 170.3 per cent. In the first two quarters of 2021, the corrugated board industry posted strong year-on-year sales growth of 7.6 and 10 per cent respectively - but again, growth and revenue are out of proportion to the cost increases in raw materials and energy.

Along with pulp and waste paper, inks are essential for a functioning printing industry. But ink manufacturers are also complaining about difficult supply chain conditions for raw materials, packaging and freight. For example, Stefan Schülling, member of the board of Epple Druckfarben AG, views the development with concern: "The increased costs for raw materials including pigments and plant-based oils, the shortage of upstream petrochemical supply chains and the high freight and packaging costs are destabilising the entire printing value chain."

This fear is shared by Sönke Boyens, chairman of the VDM North-West and vice-president of the Bundesverband Druck und Medien: "The unacceptable situation on the paper markets must be ended as soon as possible. This can only happen in a dialogue based on partnership - we demand this dialogue and are available for it."

Because when paper purchases are made without clear price commitments and delivery dates, this creates uncertainty among print service providers: "Plannable and economic production is hardly possible this way. Printing house customers are also forced to order in ignorance of the price and delivery date," says Oliver Curdt, managing director of VDM Nord-West.

The German Printing and Media Industries Federation (bvdm) is also concerned. (bvdm) is also concerned about the situation regarding prices and delivery conditions for paper. Despite a certain sympathy for the supply partners, it warns urgently of the effects on printers and their print products: "If print products are no longer delivered as agreed and reliably, this reinforces the trend towards online communication. This harms the manufacturers of print products as well as the suppliers. It's about the famous same branch that both are sitting on."

3.2 Bleak prospects? - The business climate in the printing industry

Even if the circumstances are not the best - compared to the previous month, the mood in the print and media industry brightened again somewhat in December 2021. While the seasonally adjusted business situation index fell by 2.5 per cent in November 2021, it rose by 2.3 per cent in December 2021. At 102.1 points, it was even slightly above the pre-crisis level of February 2020. Primarily due to the Christmas business, companies' production activity increased on balance - 48 percent of companies even worked overtime, which means an increase of 21 percent compared to the previous year - and short-time work also fell from 17 to 13 percent. Advertising printers with 59 per cent and packaging and label printers with 55 per cent were particularly positive about the current business situation.The development of the business climate index for the coming six months is a good indicator of the production trend in the print and media industry - here the 9 index rose by 2.3 per cent, but at 101.8 points was 2.8 and 1.1 per cent below the previous year and pre-crisis levels respectively. The seasonally adjusted balance rose to 73 per cent - an all-time high.Expectations for business development in the first half of 2022 are cautious among companies - only 8 per cent expect a favourable, 23 per cent a weaker development of business.

In response to the ongoing supply difficulties, which are also unlikely to improve from a business perspective, 73 per cent of manufacturers will increase their sales prices in the first quarter of 2021, an increase of 68 per cent compared to the previous year.

Above all, companies in the printing and media industry are also concerned about social and economic problems caused by new coronavirus mutations - primarily by the new highly contagious omicron variant. This is one of the reasons why the Federal Ministry of Finance and the Federal Ministry of Economics are extending support for companies that are severely affected by sales slumps due to the pandemic.

Bridging Aid III Plus will essentially be continued as Bridging Aid IV until the end of March 2022. Affected enterprises will continue to receive the reimbursement of fixed costs - particularly severely and closure-affected enterprises will additionally receive an equity grant, which has been adjusted and improved in Bridging Assistance IV.

The basic application requirement for receiving Bridging Assistance IV continues to be a Corona-induced decline in turnover of 30 percent compared to the 2019 reference period. The maximum subsidy rate is 90 percent if a decline in turnover of 70 percent has been recorded. The eligible cost items also remain largely unchanged - costs for rent, lease, interest expenses for loans, maintenance costs and insurance premiums can be subsidised with a maximum of 54.5 million euros per enterprise and enterprise group. A maximum of 10 million euros in funding per month is possible, taking into account all the requirements of state aid law.

Companies that are particularly hard hit by closures due to the pandemic will receive an additional modified and improved equity grant to strengthen their substance. In the event of a sales slump of at least 50 percent in December 2021 and January 2022 due to Corona, they can receive a supplement of up to 30 percent on the fixed cost reimbursement in Bridging Assistance IV.

3.3 The future with Corona - trends and outlook for 2022

The early 2021 market report from cloudprinter.com, the global cloud-based print job platform, has drawn four key conclusions based on 65,000 (digital) print products from over 1.3 million print jobs. The impact and consequences of the Corona pandemic on the global print industry are in line with global e-commerce statistics:

- existing industry trends will accelerate - e-commerce will grow continuously in the B2B and B2C sectors

- Demand for automated and integrated workflow systems is increasing, the Amazonisation of the entire e-commerce is unstoppable

- as highly qualified personnel are hard to find, the complexity of the systems must be modified in terms of simpler operation

- a return to old business models is not yet foreseeable - the situation requires a transformation of the companies to meet the demands of the customers

The intensification of online retailing by Corona leads to a restructuring of packaging production and product marketing - dynamic packaging with its automated workflows becomes part of the digital strategy for the ideal positioning of a brand and also changes the function of packaging:

- For 80 per cent of brand owners, secondary packaging not only has a protective function but is a central individualised marketing tool where impression and feel count

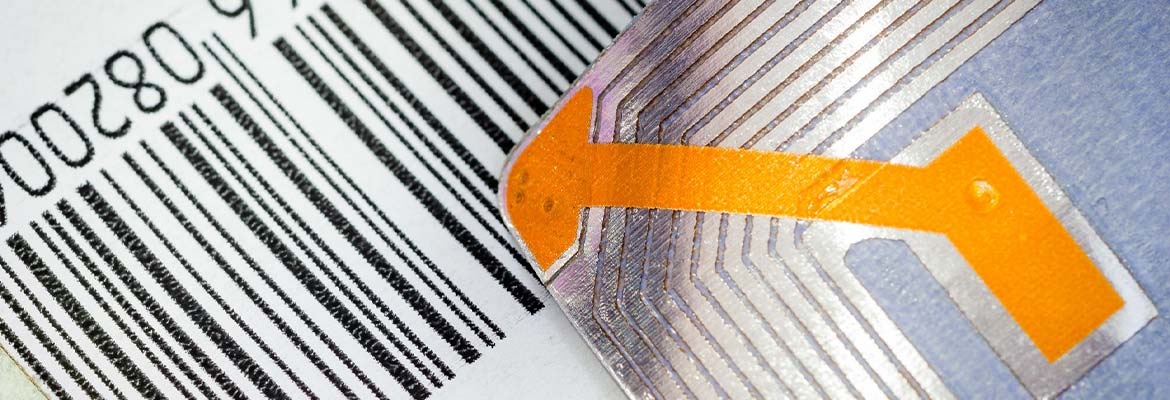

- interactive technologies such as augmented reality and QR code links become more integral and a part of the ordering process

- Easy-to-open shipping packaging is essential for a successful unboxing experience

- In order to meet the sustainability requirement, safe packaging must use as little material as possible.

- the company's own storytelling connects the brand with an attitude and provides interactivity with the customer as a brand ambassador

Another aspect of e-commerce in packaging products is the ever-shorter time-to-market, which means that brand teams are creating new products and packaging for the relevant community ever faster. The main focus is also on the social media area, for which content and images, as well as audio and video contributions, are created. In the course of this, a high degree of process automation and the use of 3D tools are essential for a successful presentation of the products in order to feature "automated packshots", which are much more flexible than product photos, on the websites. Virtual shops, on the other hand, enable companies to test customer interest quickly and reliably - "brand platforms" ensure that the same information and values of product and brand are communicated on all channels.

The categorisation as "green" packaging printing in the new field of sustainable packaging is an advantage for digital printers who provide the necessary flexibility in production to meet the new requirements of meaningfulness and uniqueness. Thanks to digital printing it is possible to produce quickly, cost-effectively and individually for segmented target markets, and the possibility of setting up hybrid systems with flexo printing combines the advantages of both printing processes.

Sustainability and environmental issues have become a top priority for brand owners, retailers and even packaging printers themselves. Sustainability in packaging influences design, substrate selection, the printing process and the choice of service provider. As a rule, due to the sustainable and ecological orientation of many producers, the storytelling around the brand image is also part of the most transparent ecological production possible - with the customer as the addressee.

Digitisation and sustainability are therefore also the topics of the future for companies in the printing and media industry. It remains to be seen to what extent the current supply bottlenecks and price explosions will persist and to what extent printing companies will be affected by the development.

These articles might also interest you:

Megatrend Silver Society and the impact on the packaging industry

Society is getting older and older: between 2000 and 2018, the proportion of people over the age of 65 increased by almost 10 per cent, according to the Federal Institute for Population Research. Senior citizens thus make up around one-third of the total population, and the trend is still rising.

Safety first: How packaging provides more safety

Packaging offers safety on various levels, because it not only protects the packaged goods, it is also an important means of ensuring for the manufacturing companies and customers alike that the packaging really contains what it is supposed to contain.

Labelprint24 - Calculate bag packaging live and delivery in record time!

Labelprint24 continues to expand its product range and in the future will also offer pouch packaging in various designs in addition to roll labels, folding boxes and tubes. To this end, Labelprint24 invested in a new, larger printing machine and a pouch machine in 2020.

Roll labels request form

Roll labels request form  Booklet labels request form

Booklet labels request form  Folding boxes request form

Folding boxes request form  Custom made shipping boxes request form

Custom made shipping boxes request form  Package leaflets request form

Package leaflets request form  Laminate tubes request form

Laminate tubes request form