- More than 18 million tonnes of packaging waste are generated in Germany every year.

- The new Packaging Act, the EU Waste Framework Directive and EN 13432 contain strict specifications for the production, composition and recycling of packaging.

- Although compostable packaging offers advantages, it also poses an immense challenge for manufacturers due to the strict legal requirements.

- Industrial composting is only a real solution under the right conditions.

(Environmental) balance: Packaging and sustainability

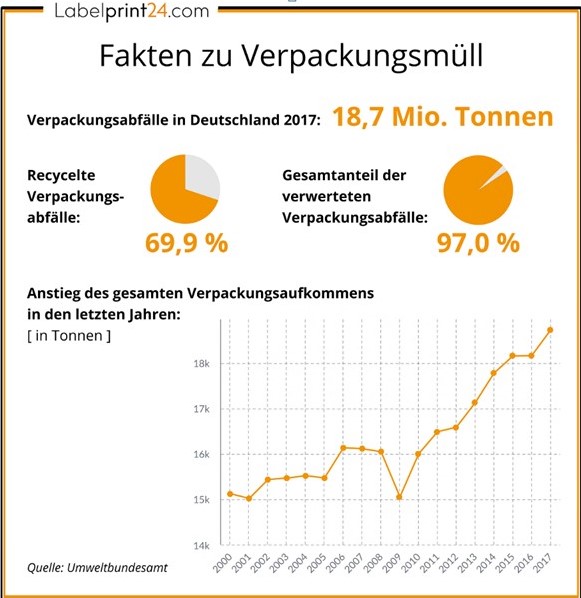

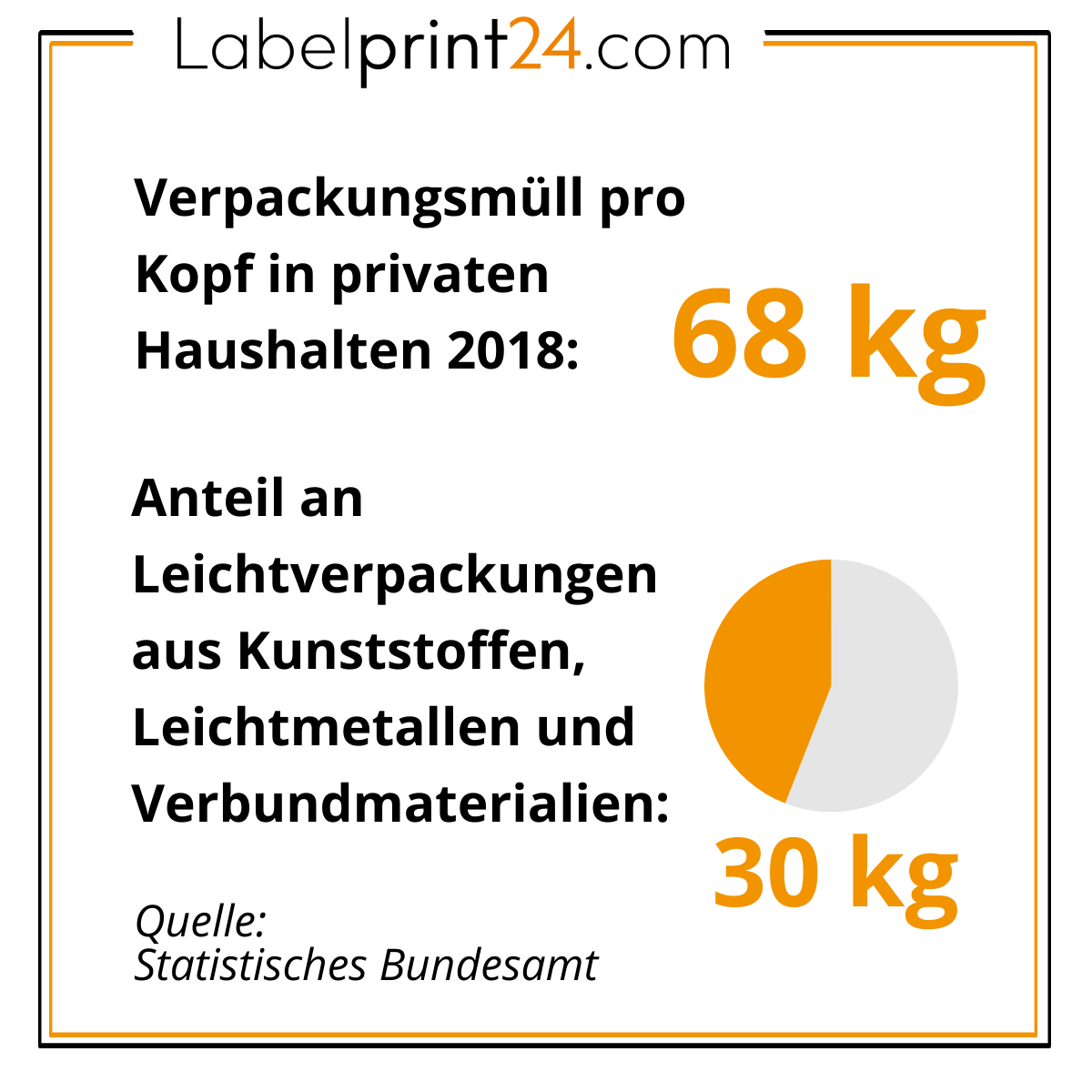

Packaging waste is a significant problem, especially in the quantities generated today. In Germany alone, the total amount in 2017 was 18.7 million tonnes, according to the Federal Environment Agency. The Federal Statistical Office indicates a collected packaging waste volume of 5.7 million tonnes for 2018, and that only in private households.

Part of the problem is that packaging is unavoidable. As transport, outer or sales packaging, it protects almost every conceivable good. Since 1991, the Packaging Ordinance has ensured that the associated waste is disposed of in an environmentally sound manner and integrated into a circular economy. And the ordinance is working: Almost 70 per cent of packaging waste could be recycled in 2017, and the overall recycling rate was 97 per cent. However, sustainable waste recycling and avoidance already begin with the production of packaging materials. Materials that are easier to recycle and require fewer resources in production also improve the eco-balance within the entire materials cycle.

Legal requirement: Recycling rates for packaging waste must increase

The new Packaging Act (VerpackG), which has replaced the Packaging Ordinance, has been in force since 2019. It essentially revolves around the regulation of product responsibility for packaging. The law stipulates that manufacturers of packaging are responsible for proper disposal. Two measures are intended to help with this:

- Anyone who places packaging products on the market must register with the Central Authority, including a mandatory quantity report and declaration of completeness. The aim of this registration obligation is more transparency and better monitoring.

- The already high requirements for the recyclability of packaging are increasing significantly with the Packaging Act. From 2022 onwards, recycling rates for some materials will be up to 30 percent higher than before.

The dual systems must submit a report on the implementation of the requirements to the Central Body and the Federal Environment Agency every year. They are also obliged to create incentives to increase the use of highly recyclable materials and packaging with high material recyclability.

Apart from that, it is of course in the interest of producers to produce as sustainably as possible. Sustainability as a purchase criterion is now widespread among consumers, and the ecological advantages lie with the producers in many respects.

What does compostability mean on an industrial level?

Higher recycling rates for all packaging materials naturally also entail a more intensive examination of suitable materials and processes. Biodegradable packaging in general and compostable packaging in particular should help to avoid petroleum-based plastic packaging as much as possible in the future.

In addition to the certificates for industrial compostability, there are additional certification systems for plastic packaging that can be broken down in home compost.

The dimensions of disposal and recycling are on an industrial level. This is not only due to the gigantic amounts of packaging waste that have to be processed. Compostable plastics also require other conditions in order to decompose as desired.

EN 13432: Clear rules for compostability

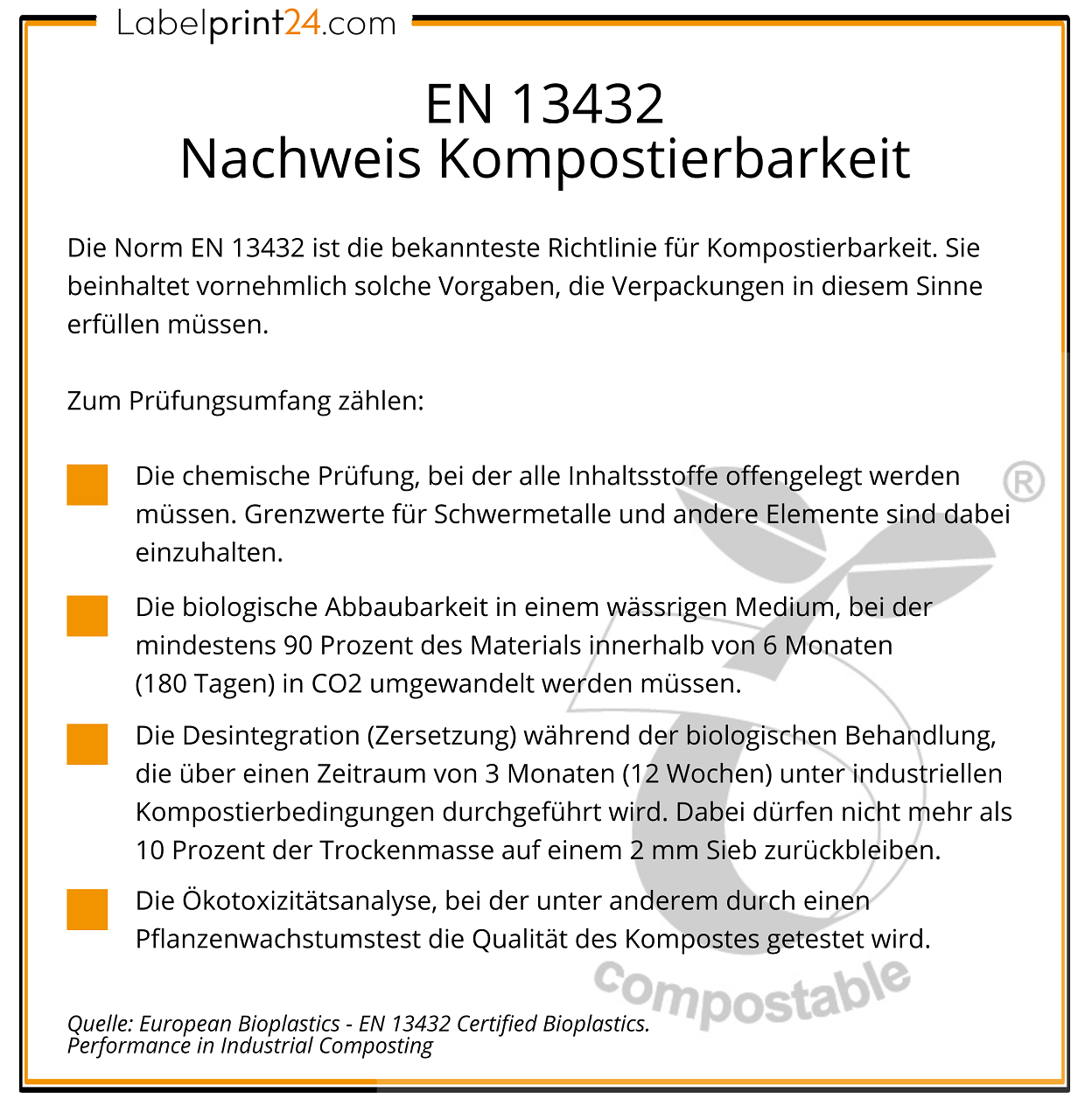

The requirements that plastic packaging must meet in order to be considered compostable are laid down in the EN standard EN 13432.

It contains specifications on limit values for heavy metals and other elements contained. Conditions for biological degradation, the results of the decomposition processes and the effects on the quality of the compost are also defined there.

These requirements are tested using various test methods. If a package can meet these tests, it receives a certificate confirming its compostability. The certification is also tied to specifications. For example, EN 13432 requires that all packaging materials used must be compostable and must not contain any environmentally harmful additives.

Compostability vs. everyday practice: A difficult relationship

Many packages consist of more than one material. As soon as plastic is also involved, it becomes more difficult to return it to the material cycle. The high demands placed on compostable plastic packaging also make development a real challenge for manufacturers. This does not only apply to the properties that the materials used have to demonstrate.

Above all, it must always be weighed up against each other how the demand for the exclusive use of biodegradable plastics relates to everyday suitability.

This applies both to production (including the specifications for the protection of the packaged goods) and to use. Reclosable bags or similar packaging, for example, offer the consumer a high degree of convenience, but can hardly be produced on a fully biodegradable or compostable basis according to the current specifications.

In terms of compostability, satisfactory solutions are therefore not always possible or available. Under such conditions, either patience is required until such innovations are feasible or manufacturers resort to alternatives. Against this background, recycling is gaining even more importance for the packaging industry as a sustainable alternative.

From packaging to compost: Industrial composting of plastic packaging

For the handling of waste in general, the EU Waste Framework Directive (2008/98/EC) sets the guidelines for the national legislation of the Member States. Article 4 includes the waste hierarchy, in which the prevention of waste is the desirable top.

Below that, different methods of waste treatment follow, with disposal without any recovery of energy or raw materials as the lowest level. In between are different levels of recycling, all of which are theoretically possible for biodegradable plastics.

Industrial composting falls within the scope of material recycling and is usually carried out in three steps:

- Preparation phase: In a first step, the waste is shredded and homogenised. This involves multiple rearrangement so that the components mix better together.

- Intensive rotting: For the desired decomposition process, oxygen and moisture are added under controlled conditions during intensive rotting. This creates optimal conditions for decomposition.

- Post-rotting: In the final step, the decomposition processes already subside and ensure stabilisation of the material. In this way, the fresh compost becomes finished compost.

However, there are different guidelines across the EU when it comes to the treatment of biodegradable plastics in the context of composting.

Compostability - a critical look

However, an important aspect to consider in connection with the industrial composting of plastic packaging is the benefit of the method. According to the Federal Environment Agency, composting only makes sense if the degradation results in an additional benefit. For biodegradable plastics, this is generally only possible in exceptional cases and is even viewed sceptically for compostable packaging in particular. The Bundesgütegemeinschaft Kompost e.V., for example, is critical of various aspects of composting, including

- the lack of benefit of biodegradable plastics for the necessary degradation processes,

- the non-utilisation of the energetic value of this waste, and

- the risk that after treatment there are still particles in the compost that can be considered foreign matter.

In this respect, compostability for plastic packaging is only purposeful if it brings a real benefit within the recycling cycle. The fact that plastics made from renewable raw materials have this potential cannot be denied, if only because of the possible conservation of resources.

When it comes to recycling, however, the costs and results of the processes used must be taken into account. If these only meet the requirements and expectations in a small number of cases, other methods such as recycling may be the better alternative.

These articles might also interest you:

Compostable, Recyclable and Co

The topics of nature conservation, environmental protection and sustainability are becoming increasingly important in all areas of life. Sustainable and recyclable materials are therefore an important factor in our industry.

The comparison: compostable or conventional packaging?

The share of biodegradable or even compostable packaging - measured against the total amount of packaging waste - is still low.

Natural cardboard for folding boxes that inspire

Natural cardboard has gained considerable popularity as a packaging material in recent years. Packaging often consists of the well-known plain brown cardboard.

Roll labels request form

Roll labels request form  Booklet labels request form

Booklet labels request form  Folding boxes request form

Folding boxes request form  Custom made shipping boxes request form

Custom made shipping boxes request form  Package leaflets request form

Package leaflets request form  Laminate tubes request form

Laminate tubes request form