With our digital printing systems, we are able to customise roll labels with custom data, including such things as sequential numbers, codes, or changing print designs. For smaller and medium-sized print runs, labels are less expensive to produce digitally. For larger print runs, flexographic printing is more affordable. There are also a few more choices in materials available when choosing flexographic and offset printing.

3. Materials for roll labels

Generally speaking, printed self-adhesive labels, whether as rolls or sheets, consist of several layers, including a backing material (lining), a pressure sensitive adhesive, a surface material (facestock), and ink . Optionally, a transparent coating and/or metallic foil can also be applied. After printing, roll labels are rolled up in the number specified by the customer around a carton core. The facestock material of the labels carries the printed image or wording and may consist of label paper or foil.

3.1 Label paper

Labels printed on label paper are the most affordable. However, they are only usable for a short time whether outdoors or in or in places where they are sufficiently protected against moisture, wind and weather. There are many types of label papers with different weights, surfaces, and textures. An optional blue coating on back can make the label paper more opaque. A special label paper for use on pharmaceuticals is less thick and thus more supple, allowing it to adapt perfectly to curved surfaces like those found on ampules.

3.2 Metallicised paper labels

Labels printed on metallicised paper have a layer of fine-laminated aluminium foil which is applied to the paper surface during the production process. This film has a metallic gloss like silver or gold. This paper is ideally suited if the labels are to have a high-quality, metal-like effect as often seen on cosmetics.

3.3 Fluorescent paper labels

Labels printed on fluorescent paper send strong messages and are most often used as price tags. The typical yellow, red, orange, or green colour are created by pigments painted on the label paper during production.

3.4 Printed labels made of thermal paper

The best known application of printed labels made of thermal paper are the roll labels for self-service printing at supermarkets. The label printers integrated into these scales print individual labels with an EAN or barcode, weight, and price, i.e data collected just moments before printing. The typically black printing on thermal paper labels is caused by a special reactive ink applied by the paper manufacturer to the base label paper. Important in the production of thermal roll labels for self-service printing is the protective layer on the surface that prevents the reaction ink from being activated while still in the printer.

3.5 Printed labels on plastic film

Printing labels are increasingly being made of plastic. Plastic labels, such as PE, PP or PVC, have certain advantages over paper labels. They can even be used outside without problems. Labels printed on plastic are extremely robust and offer outstanding resistance against environmental influences such as moisture, acids, chemicals, UV radiation, or grease. Plastic labels also make transparent labels possible. Transparent stickers are used to label cosmetics and drugstore products. The message printed on transparent labels appears as if it had been printed directly on the product. The transparency of this "invisible" printed label lends the product a high-end appearance.

3.6 Backing material

The backing material to which the labels are attached after printing before they are applied consists of thin glassine or kraft paper or a special plastic material for high-volume labelling machines. The printed label is easily separated since the lining is often fitted with a silicon release layer on the adhesive side of the label. The backing material is no longer needed after the label is applied and is subsequently disposed of and recycled.

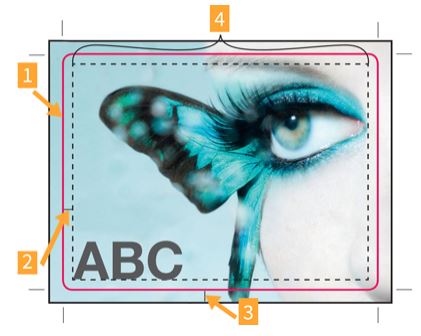

4. Processing and finishing

After printing, the printed labels can be further processed and refined. The refining process includes coating and laminating, hot foil stamping, or the application of tactile symbols, such as a warning triangle for the visually impaired. The printed and finished labels then still need to be punched into their final form. To do this, labelprint24 uses both a laser punch and a mechanical rolling punch with a die made of metal. The laser punch cuts the printed labels from the layers without damaging the lining and in contours of any shape and size. For labels with indirect food contact you will find the right label of your choice among our

food labels.

5. Winding labels on the roll core

Presenting printed labels on rolls means they will need to be wound onto a roll after printing. A roll core made of thick carton which matches the diameter of the customer's existing label dispenser is needed. Theoretically, any roll core diameter is possible, but in practice, the standard diameters 26, 40, 50 and 76 mm are most common. When wrapping on the roll core, the winding direction is important to ensure that the labels are properly dispensed on the customer's product. Basically, printed labels are either rolled facing the inside or the outside of the roll.

6. Dispensing labels

The finished label rolls are packed and delivered to the customer, ready to be placed in the existing label dispenser. The width of the existing devices ranges from simple table-top label dispensers to hand-held labellers to fully automated high-output labelling machines that can label thousands of products an hour.

6.1 Manual dispensers for printed roll labels

With table-top label dispensers, the individual label rolls are just inserted and the roll labels are individually pulled off by hand. Table-top label dispensers fit any deself-adhesive and are often found in home offices. The dispensing speed is not so important here. The focus here is on orderly and clean storage of the labels until required.

Handheld dispensers feed the printed roll labels by pressing a lever on the handle. A rubber roll peels off the individual label and applies it. This method works quite quickly but is still far too inaccurate and too slow for large quantities of labels.

6.2 Dispenser systems for printed roll labels

For the application of large quantities of printed labels, automatic labellers of various speed classes are used; most are integrated into factory packaging lines. A conveyor belt moves the products past the labelling machien and photoelectric sensors detect the optimal label position. The printed labels are controlled by a microprocessor and placed precisely on the product packaging as instructed. There are high-speed labellers that can apply up to 5,000 labels per minute.

Customer Testimonials: 759

Customer Testimonials: 759